JPM Software

Our website has the best online gear calculation programs including cylindrical, conical, worm gears, wheels for gear milling machines, bearing sizing, sliding bearings, shafts and much more.

Cylindrical gears

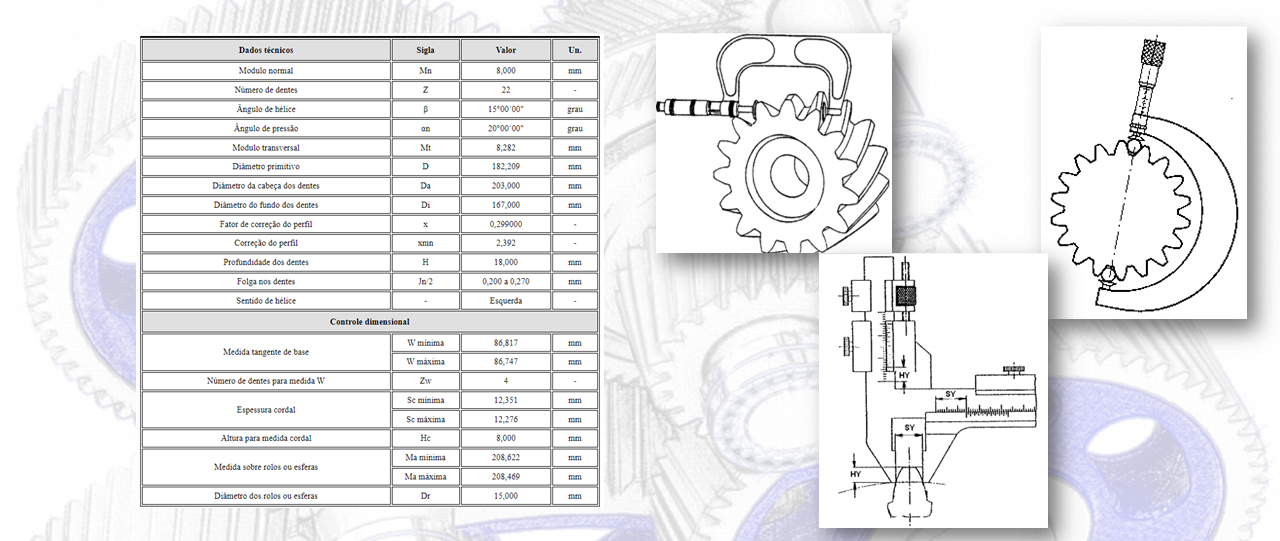

Single gear calculation

In this program, you simply need to inform the normal module, number of teeth, pressure angle and helix angle and the program will calculate the external diameter using the correction factor or the correction based on the external diameter, minimum and maximum clearance, number of teeth for measurement W, base tangent measurement W, height for chordal measurement, chordal measurement at the determined height or at various heights, thus being able to measure the profile, roller diameter for measurement over rollers and the measurement over rollers. The program calculates for cylindrical gears with internal and external straight and helical teeth.

Watch the videoGear set calculation N

In this program, you simply need to inform the normal module, number of teeth, pressure angle and helix angle and the program will calculate the external diameter using the correction factor or the correction based on the external diameter, minimum and maximum clearance, number of teeth for measurement W, base tangent measurement W, height for chordal measurement, chordal measurement at the determined height, roller diameter for measurement over rollers and the measurement over rollers. The program calculates for a set of cylindrical gears (pinion and crown) with external straight and helical teeth.

Watch the videoGear set calculation R

The program makes the same calculations as the “N joint milling form”, but in this program we have the option of reducing the thickness of the crown teeth and compensating for it on the pinion or vice versa.

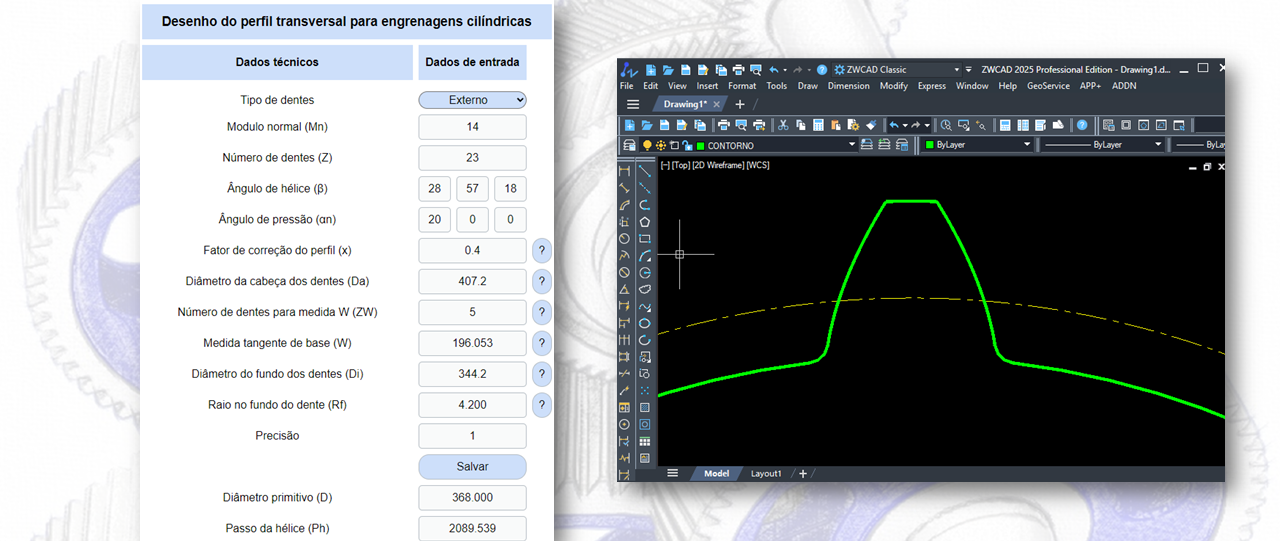

Watch the videoGear tooth profile drawing

Enter the normal module data, number of teeth, pressure angle, helix angle, profile correction factor, tooth head diameter, tooth casting diameter, number of teeth for W measurement, base tangent measurement and the program will download a .lisp file that when loaded by AutoCad draws the cross-sectional profile and can be used to create 3D to be used in CAM.

Watch the videoCalculation of power of a pair of gears

Calculate the power (resistance to pitting and bending of the teeth) of a set of cylindrical gears with straight, helical and bi-helical teeth for open drives, low and high speed reducers and mill gears. The calculation takes into account the geometry of the set, material, heat treatment, quality, etc.

Watch the videoQuality of gear teeth

Calculation of the quality level according to the DIN standard from level 1 to 12 and also level conversions for AGMA, ISO and JIS standards.

Watch the videoBacklash on the teeth of a gear

Find the clearance in the teeth, with this program it is possible to find the clearance in the teeth of an existing set, being required to inform the normal module, number of teeth, pressure angle, helix angle, center-to-center measurement, pinion outer diameter and the base tangent measurements W found in the pinion and gear.

Watch the videoForces resulting from a gear

Determine the resulting force of a set of gears, with the value of these forces we can determine the shaft, bearings and bronze and patent metal bearings.

Watch the videoGear contact correction

You assembled a gear, made the contact and stayed out, in this program you must place a shim in the bearing until the contact is distributed and with the measurement of the shim find the error of the propeller to correct the machine.

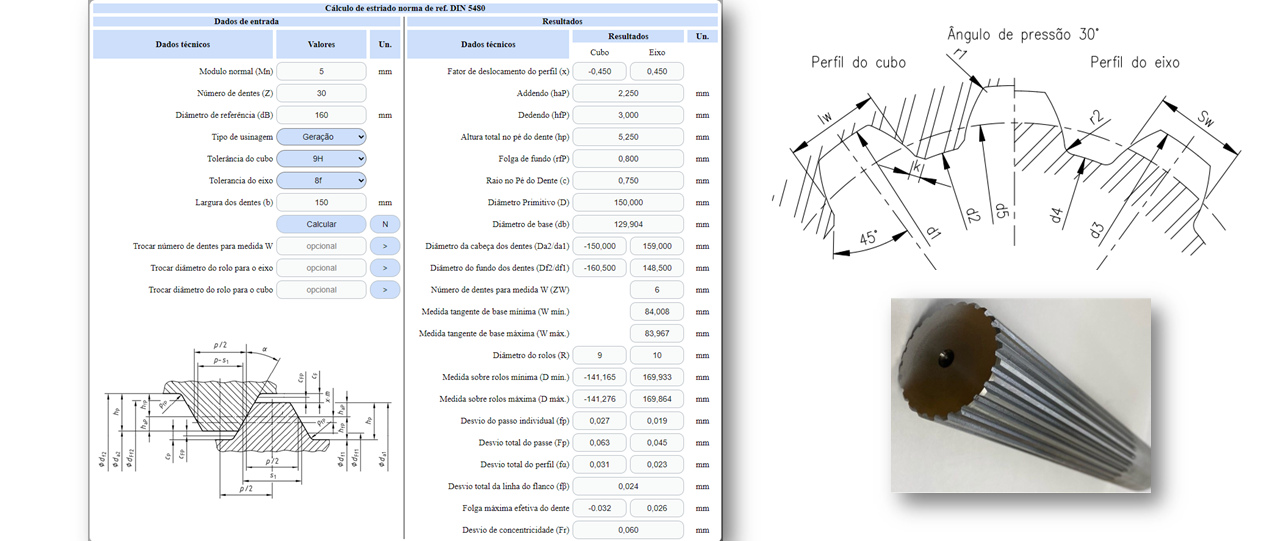

Watch the videoDIN 5480

Calculate diameters, tooth thickness, groove tolerance, just enter the normal module, number of teeth and reference diameter.

Watch the videoDIN 5482

Calculate diameters, tooth thickness, groove tolerance, just choose the nomenclature.

Watch the videoDIN 5480 Resistance

Profile correction

Calculate a profile correction according to the transmitted power.

Watch the videoANSI B92.1

Calculate diameters, tooth thickness, groove tolerance, just enter the normal module, number of teeth and reference diameter.

Watch the videoChordal > W

Find the base tangent measurement (W) by informing the chordal thickness and height.

Watch the videoAccumulated step

Calculate the cumulative pitch of a spur, helical, and bi-helical cylindrical gear.

Watch the videohobbing machines gear changing

Gear hobbing wheels

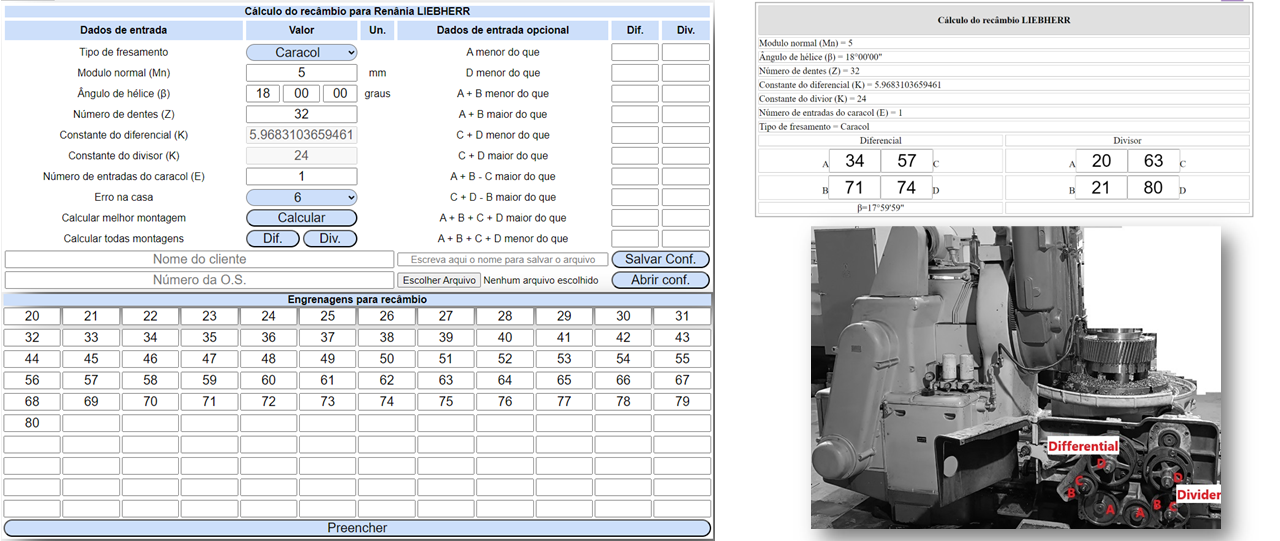

Calculate and gear train for Fellows, Maag, Renania milling machines, universal milling cutter, tooth grinding quickly and accurately, being able to determine the minimum and maximum number of wheels and also assembly conditions.

Watch the videoGear Maag wheels

Calculate and gear train for Fellows, Maag, Renania milling machines, universal milling cutter, tooth grinding quickly and accurately, being able to determine the minimum and maximum number of wheels and also assembly conditions.

Watch the videoUniversal milling machine

Calculate and gear train for Fellows, Maag, Renania milling machines, universal milling cutter, tooth grinding quickly and accurately, being able to determine the minimum and maximum number of wheels and also assembly conditions.

Watch the videoBevel gears

Calculation of power of a pair of gears

Calculate the power (resistance to pitting and bending of the teeth) of a set of straight-toothed bevel, spiral, zero and duplex gears. The calculation takes into account the geometry of the set, material, heat treatment, quality, etc.

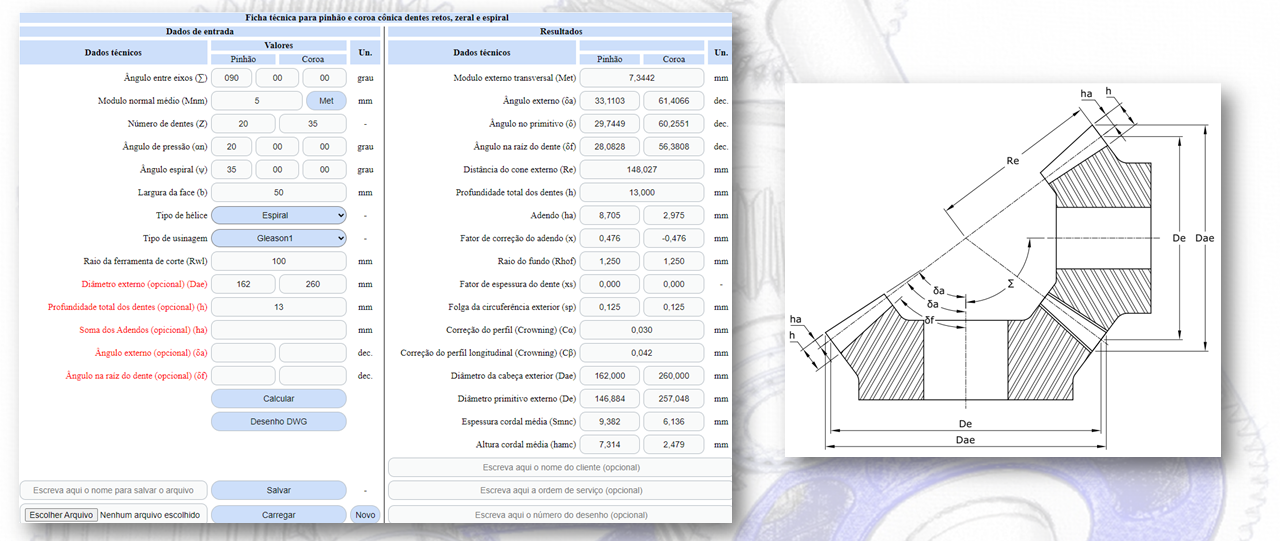

Watch the videoGear set calculation

Calculate the diameters, addendum, tooth depth and head angles, pitch and tooth bottoms for Gleason and Klingerberg bevel gears.

Watch the videoWorm gear

Globoidal

Calculate all dimensions of a GLOBOIDAL crown and worm gear set and also the power calculation that the set supports. In addition, the program provides a video instructing how to draw the GLOBOIDAL worm in 3D. In the program, the user will download the coordinates, matrix and equations to build the 3D.

Watch the videoCommon

Calculate all dimensions of a set of crown and worm gears by providing the axial module, number of crown teeth, number of worm entries and worm outer diameter. The program will also calculate the power that the set supports.

Watch the videoBearing

Bearing with forced lubrication

With the calculation of bearings with forced lubrication, the user will determine the bronze or meta patent bearing, its capacity for the force applied to the bearing, Reynolds formula and the temperature at which it will work.

Watch the videoBearing with gravity lubrication

With the calculation of bearings with gravity lubrication, the user will determine the bronze or meta patent bearing, its capacity for the force applied to the bearing, Reynolds formula and the temperature at which it will work.

Watch the video

Input shaft bearing calculation

According to the forces of a gear set and the chosen bearing, the program will determine the service life of each bearing considering the radial and axial forces.

Watch the videoIntermediate shaft bearing calculation

According to the forces of a gear set and the chosen bearing, the program will determine the service life of each bearing considering the radial and axial forces.

Watch the videoOutput shaft bearing calculation

According to the forces of a gear set and the chosen bearing, the program will determine the service life of each bearing considering the radial and axial forces.

Watch the videoGear oil flow

Calculate the oil flow required for a set of gears (pinion and crown).

Watch the videoGear oil shower

By providing data such as lubricating oil flow and number of holes, the program determines the diameters of the holes for the oil to exit.

Watch the videoForce distribution by support

Define the forces received by the bearing or bushing according to the gearing.

Watch the videoShaft

Flexure in a driven single shaft

Determine with the drive data (pinion and crown) and the hardness of the material, the program will provide the minimum shaft diameter, allowable material stress, material tensile strength and the bending moment.

Watch the videoShaft torsion calculation

Determine with the power, rotation and material hardness data the program will provide the minimum shaft diameter, allowable material stress, material tensile strength, bending moment and torque.

Watch the videoCalculation of flexure in driven double axle

Determine with the data of two drives (pinion/crown and pinion/crown) and the hardness of the material the program will provide the minimum shaft diameter, allowable stress of the material, tensile strength of the material and the bending moment.

Watch the videoCalculation of deflection on axis

Program to correct the helix angle due to shaft deflection, that is, when the shaft undergoes bending during work, the tooth contact is out of alignment, so it is possible to change the helix angle so that when the reducer takes on a work load, the tooth contact is distributed.

Watch the videoCritical speed

CCalcule a velocidade máxima de um eixo para redutores de alta velocidade.

Watch the videoVarious software

Draws straight MAAG tools

Watch the video

Draws oblique MAAG tools

Watch the video

Gap minimum to tools Maag

Watch the video

Minimum gap to rectify

Watch the video

Minimum gap to hobbing

Watch the video

Chain gear

Watch the video

Power and torque conversion

Watch the video

Pin calculation for case

Determine the diameter, length, and number of pins or bolts to transmit torque from a bushed pinion.

Watch the videoCalculation of torque transmitted by interference

Determine the interference between pinion and shaft to transmit torque without using a key.

Watch the video